In-house Junker test setup development

My Work | | Links:

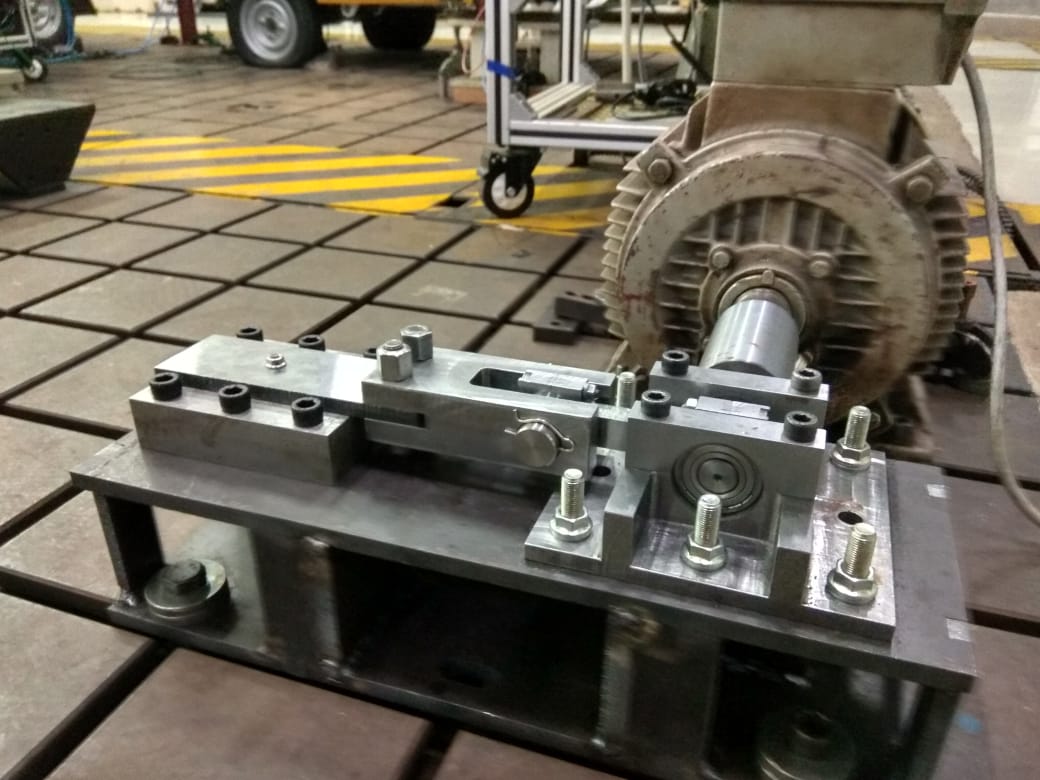

I developed a custom Junker test setup and load washer as a R&D intern at CAE Engine unit of Bajaj Auto Ltd. plant in Akurdi, Pune. Conventional junker test rigs are not flexible in accommodating variations in test specimen type or dimension and operating frequency or load. During two month long internship, I conceptualized an innovative and efficient solution for this problem by proposing a eccentric shaft mechanism that can be easily swapped to change the net displacement of part in vibrational bolt loosening, as a result, vary dynamic load on test specimen. This method also enables active operational frequency control by simply changing AC induction motor frequency in the variable frequency drive (VFD). Maximum operating frequency was also increased by four fold compared to conventional setup which is highly desirable for engine components operating at high frequency. Frequency increase directly results in reduction in run time for same number cycles. The test specimen can also be easily and quickly changed by swapping a pair of plate and clamp. After detailed design of the setup in Siemens NX (CAD), the digital twin was analyzed for failure using ANSYS Structural (Finite Element Analysis) and ADAMS MSC (Multi body simulation). The following video illustrates the working of developed prototype.

The displacement of the nut and bolt combination is not visible as the net displacement which is twice the eccentricity of shaft is a fraction of a millimeter. Finally, the prototype was demonstrated along with load vs time data acquisition. The results were compiled and analyzed. More details are available in this presentation.